Designing An Award Winning Winter Driver Safety Program

Ringway Shares How They Support Front-Line Winter Drivers

There’s no room for mistakes when it comes to risks on the road, especially during winter.

Unfortunately, many fleet safety programs are not effective or get abandoned.

David Campbell, Ringway’s Health, Safety & Environment Director, shared with us how they implemented an award-winning Winter Maintenance Driver Training Course.

Ringway is a leader in highway services for local authorities in the UK and through their wider business is responsible for maintaining and managing around 50,000 km of the UK’s highways network. Through their culture of “safety for a reason”, they:

- Identify risks in their fleet

- Engage all stakeholders on health and safety

- Invest in control measures

- Monitor outcomes to continually improve fleet safety

“Since we introduced the winter maintenance driver training, we have trained more than 550 drivers and we will continue the programme until we have a fully skilled winter maintenance driver team.” David Campbell, HS&E Director at Ringway.

Here’s how they did it.

Identify fleet risk

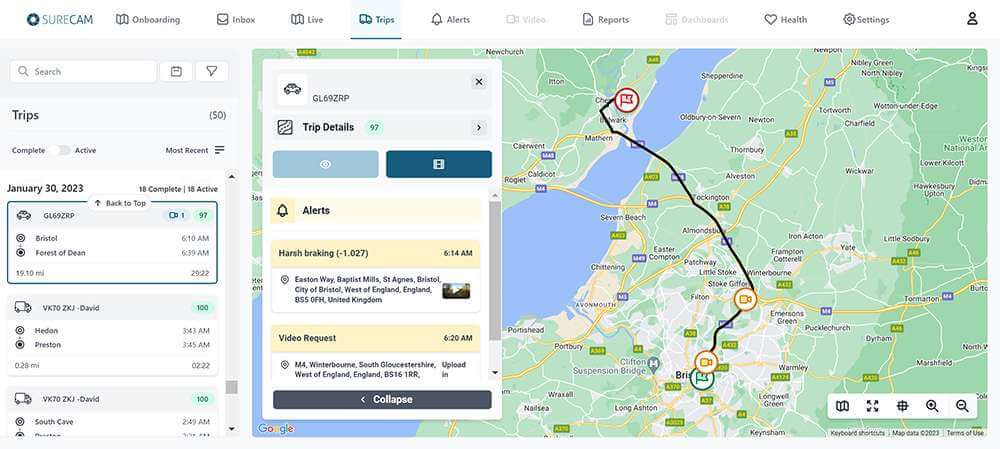

Ringway analysed data from vehicle technology including telematics, cloud-connected dashcams and collected driver feedback to identify risks in their fleets.

“We found that 7% of fleet incidents which were categorised as driver fault involved the driving of gritters.”

When road surface temperatures drop below zero degrees and there’s a risk of snow or ice, the Ringway gritting teams are responsible for treating public roads and ensuring they are as safe as possible.

Gritting is one of the most hazardous road activities to perform.

The gritting team have to drive over icy roads often at early or late hours of the day. To treat the roads, salt is applied to road surfaces out of the back of the gritting vehicle.

Even at low speeds, it takes a lot of skill to drive an 18-tonne vehicle over icy roads without risk of overturning.

Through industry research, Ringway learnt that serious accidents involving gritters that had overturned were not uncommon.

Many involved vehicles overturning in poor weather conditions and resulted in serious injury.

Invest in control measures

A successful fleet safety programme requires an investment of time and resources.

Having identified thee risk and researched training options, Ringway realised that they needed to develop tailored training to support their front-line winter maintenance drivers. It was important for the training to replicate real-life driving conditions but operate in a controlled environment. The goal was to improve gritter driver safety by equipping them with the skills needed to control a large vehicle in wet and slippery road conditions.

Ringway worked hard to find a training partner with experience in developing bespoke courses for high-risk driving situations. They selected a trainer and worked with them to ensure that the course covered common slow manoeuvres that resulted in the majority of incidents their gritters experienced.

“The analysis of the types of gritter accidents we were having as a company allowed us to understand the main risks to our drivers. We were able to develop a course that is practical, relevant and engaging.”

Engage all stakeholders on health and safety

“How do I get my drivers on board with safety technology?”

This is one of the most common questions we get asked by fleet managers. Making safety a strategic priority and using the right channels to engage drivers early on is a major success factor.

Ringway provides training to new employees to encourage buy-in to the road safety culture of the business. They actively engaged with internal and external stakeholders as well as the general public.

“The communication of health and safety and road risk is very important as we need to ensure that our workforce, supply chain partners, clients and other stakeholders are engaged in a way that is accessible to them and in a relevant format.”

For drivers and internal employees, Ringway encourages two-way communication where they share safety practices while also collecting feedback from drivers.

Communication methods used include:

- Safety meetings and team meetings

- Internal toolbox talks

- Engagement through local safety committees

- Employee nominated awards to recognise and reward safe drivers

- Employee health and safety surveys

“The benefits of the training are that our workforce is competent in winter conditions, reducing the potential of accidents. This is supported by the positive response we’ve had from our drivers. They can see that as a company we are listening to their concerns and investing in their safety.”

Monitor outcomes to continually improve fleet safety

Monitoring outcomes is one of the most important but often overlooked stages of any successful fleet safety programme.

Ringway put in place processes to regularly collect driver feedback, analyse and review trends and fleet risks. By engaging with employees, industry, partners and suppliers, Ringway had access to a variety of driver and fleet data that they could leverage to build a successful winter driving safety programme.

The results speak for themselves. Since implementing the winter training course:

- Vehicle damage costs reduced by 36%

- Significant reduction in the severity and frequency of incidents

- Ringway’s winter driving training won the CIHT award and has set a new industry benchmark

New to driver training? Need to refresh your skills?

See our Driver Coaching 101 guide to get on the right road to improved fleet safety this winter.

Book a demo today!

SureCam offers GPS vehicle tracking, live video, and real-time alerts for efficient fleet management. Get a Demo